I’ve wanted a larger press for a while now, and letterpress is somewhat limited for printing images, and I’ve always thought a litho press, or an etching press would be a great addition to the studio.

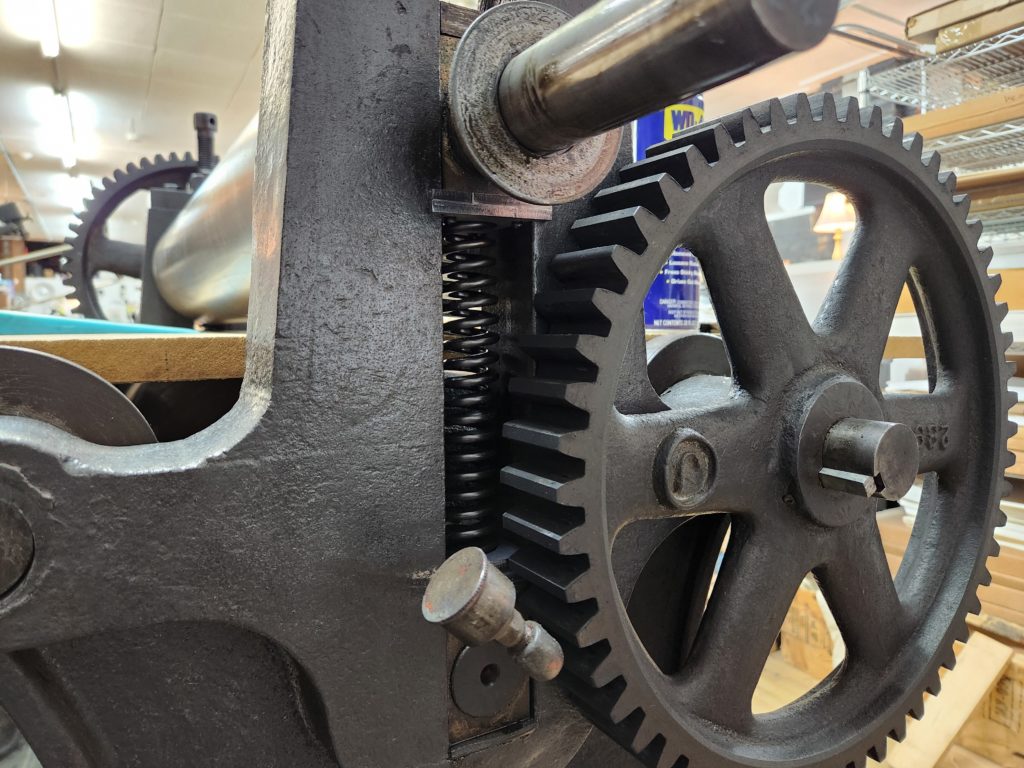

I came upon this beautiful etching press during one of my journeys on facebook marketplace, and after inspection it turned out to be complete, relatively clean and in working order. The book/nipping press at the bottom is very unique and adds great functionality and a super cool touch. Interestingly, there are no serial numbers, name plaques or other identifying marks on this press.

A little bit of digging revealed that this has to be a Sturges etching press from 1904, or so I thought. More on that later, as I have found some pretty cool details on this press.

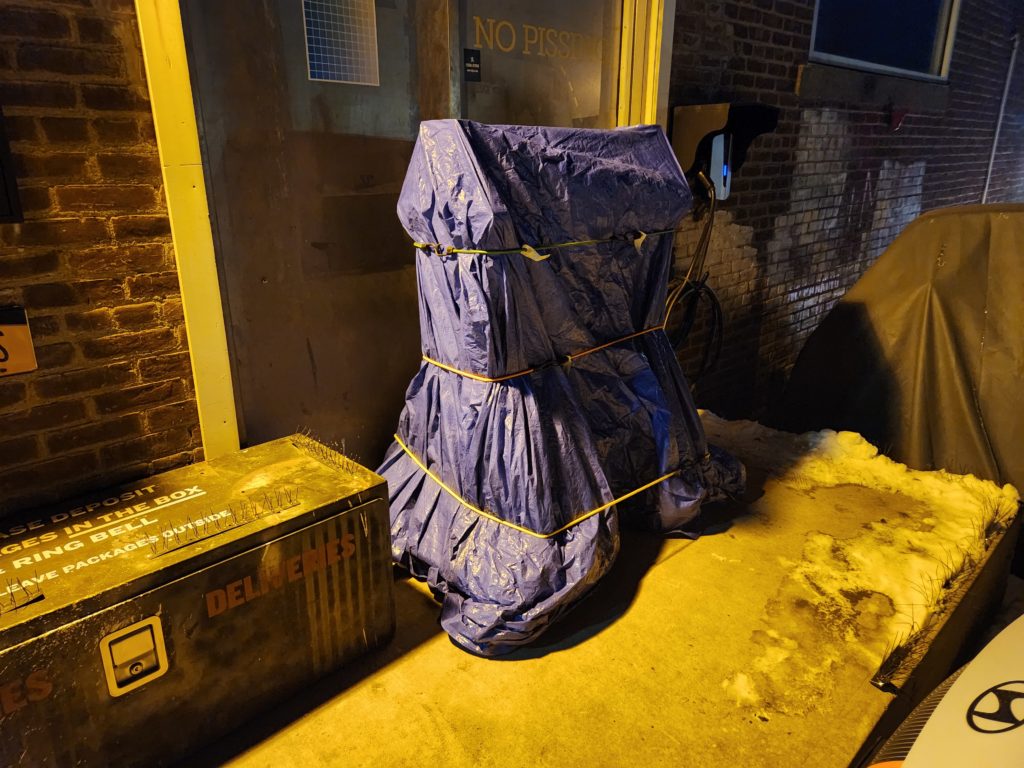

To get it back to my studio, I had to rent a truck with a liftgate and we had to partially dismantle the press to make it easier to move. Cast iron is deceptively heavy – the top cylinder is 26″ wide with a 6″ diameter, which makes it roughly 275 lbs – way too heavy to lift, even for two people. At first, we had trouble testing the press and removing the cylinder, as someone had removed the bed and a drive gear and somehow everything was wedged into place. I managed to get everything moving and check for functionality. So far, so good. We loaded the thing onto two furniture dollies and onto the truck. Fortunately, the press was sitting on ground level, and that part was relatively easy.

And here comes the fun part… The bottom cylinder has is a solid 12″ diameter which makes it roughly 650 lbs. I had to devise a plan to get the press into my studio, as my loading pad is raised and makes for a 12″ step into the space. To make matters more complicated, there’s an incline and a tight parking lot that makes loading and pulling up a truck somewhat tricky.

I have moved plenty of presses into –and out of– the space to know the complications by heart. Any sort of lift, or crane would not have enough reach to get the press inside in one piece, and the massive weight is an issue here, so I decided to partially dismantle the press. A ramp is out of the question due to the top-heaviness and prior experience. The large crank wheel and gears alone probably weigh 500 lbs, and we also removed the top cylinder before loading. The cast iron frame, book press and bottom cylinder probably add up to 1,700 lbs., and I decided to keep the frame in one piece.

On day one, we unloaded the press and I moved the smaller parts inside the studio. We figured it’s impossible to move the press inside in its current state without any sort of heavy equipment… I have muscled quite a few machines around, and this one proved to be especially tricky due to the extremely heavy 12″ cylinder, which also makes the press very top heavy.

It took me a couple of days to come up with a proper plan. After taking measurements and weight calculations I did some research, and considered an engine lift, or a gantry crane and decided to remove the cylinder in order to move this beast. A gantry would be too big and expensive, and an engine hoist would not be all that useful in the long run and take up too much space, albeit relatively inexpensive. Space is also a bit of an issue, as the loading pad is only 4 ft. deep, so I decided to make a gantry from two 300lbs ladders, some stamped metal bars used to deliver one of my UV machines, two 2″x4″ beams and a 2-ton chain hoist. Ladders are apparently rated conservatively for 4x of the indicated weight, and a pair of 2″x4″‘s should hold 1,200 lbs easily. I also found some axle straps and a lifting sling at Harbor Freight.

My gantry proved to be a little tricky, as it needed to clear 32″ inches in between and my chain hoist needed to be 9ft. high to be able to lift the cylinder – the concrete pad is just about wide enough.

Lifting the cylinder was nerve-wracking and a chain hoist is a beautiful thing to have – it makes it incredibly easy to lift the massive weight. In the end it all worked out beautifully and turned out to be relatively easy.

The press is in place and cleaned up pretty well… I treated the cast iron with a WD40 soaked rag and stove paste. I also gave the cylinder a good scrub with Bartender’s Friend and a Scotch Brite sponge. The press runs incredibly smoothly, and my first Presto litho print came out a-OK – it turns out that the top cylinder rests on the bed by gravity and has no means of adjustment, which struck me as very odd. Modern etching presses have take-up bearings and the top cylinder is generally adjustable in height. Many presses seem to employ heavy springs. Here, the cylinder bearings are simple brass journals and the top cylinder just sits on the bed. Weird, and therefore more research has to be conducted…

I came upon a handful of references to this press, mostly a smaller model said to be from 1904 – I have found two or three images online with my larger version, but not much information. None seem to have adjustable cylinders, at least I wasn’t able to identify anything in the pictures posted, until I came upon a few images of other presses… Someone said that it was common for presses of this vintage to have no adjustment mechanism, and I came upon a post where someone had added springs to a Sturges press. So, I decided to come up with my own solution.

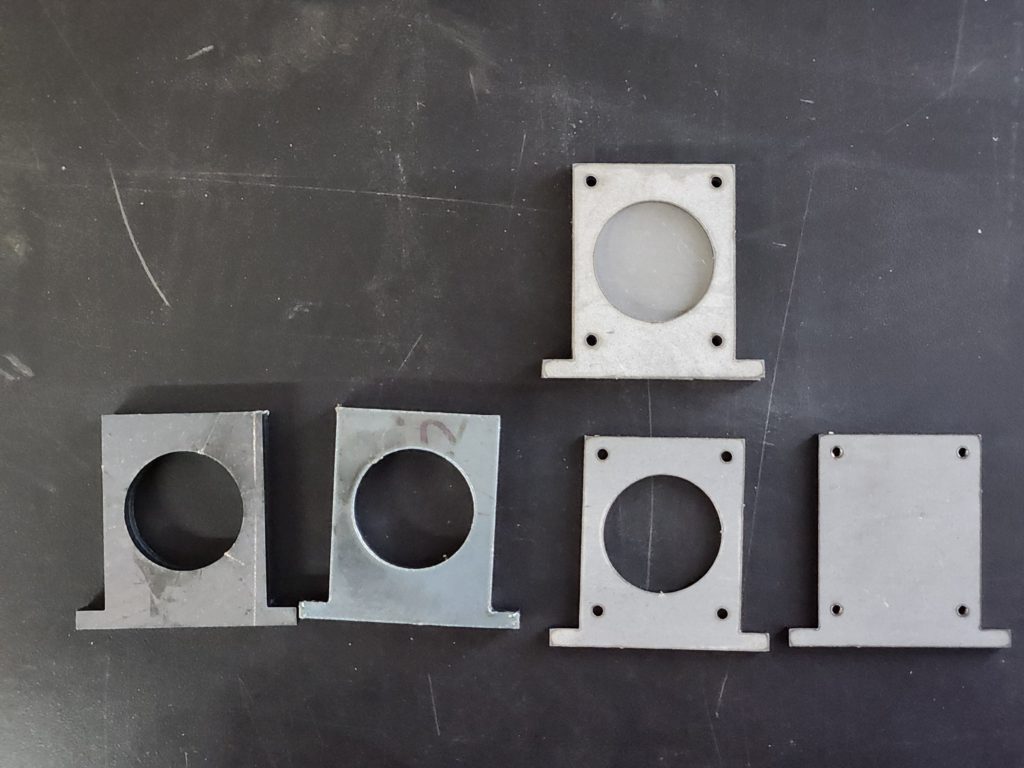

A set of springs is in order, yet – how am I going to keep them in place without them bending or sliding out of place? Exactly like the cylinder bearings, which have a protruding notch on either side of the cast iron channel to prevent them from sliding out. Pretty simple, yet effective. After taking some measurements, I found heavy duty springs on McMaster Carr and opted for 1.25″x7″ die springs which have flat bottoms and are rated for 434 lbs. Turns out, my choice of 7″ length is absolutely ideal.

I drew up my design for the spring retainers in Illustrator and had them laser cut from steel by SendCutSend. The bottom retainer plate is 1/4″ thick and the top part is bolted together from two 1/8″ steel plates with laser-cut holes and tapped threads for 3mm machine screws, which allows for the top to be closed and prevent it from sliding down. All in all a pretty cheap solution – I paid $61.03 with free shipping and the parts arrived within five days. The die springs cost $58.23

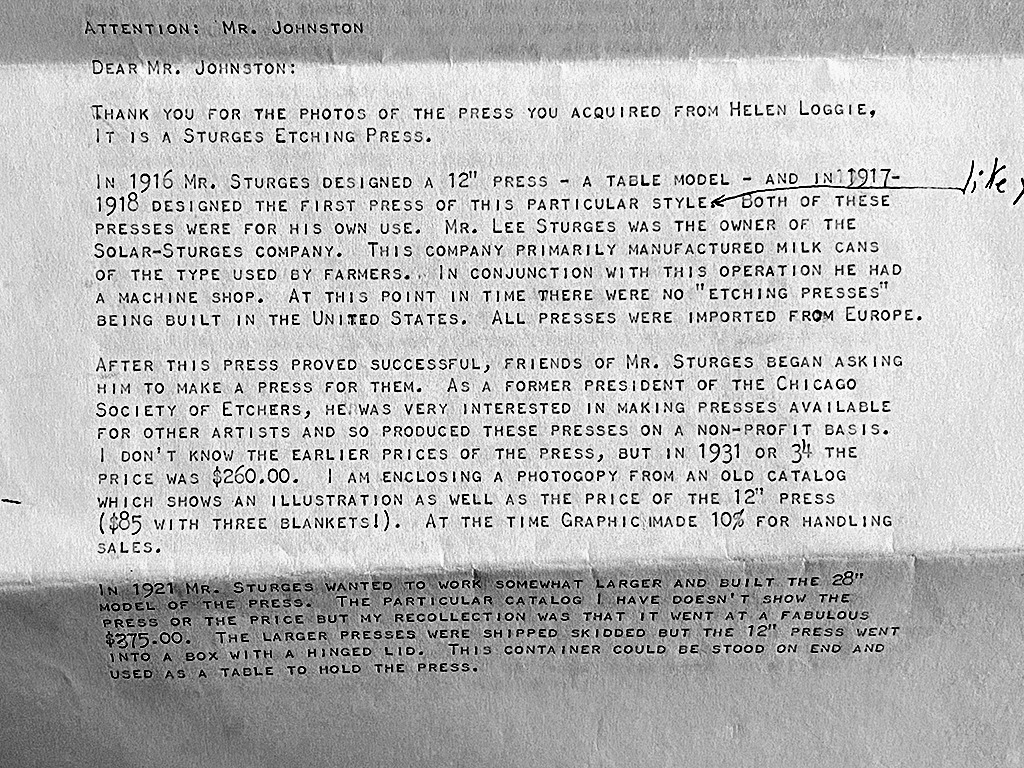

Now I have a clean 1921 Sturges etching press with an adjustable top cylinder. Also, note the grease pod by the large drive gear! The press has four of them, one for each cylinder journal. Now the most interesting part of the whole mystery… I came upon this letter during my searches, which explains how Sturges presses came to be.

Make no mistake – the Sturges looks pretty dainty next to the Heidelberg, yet it weighs almost as much… All I need now is a proper press bed & I have a large sheet of Garolite sitting around, which is hopefully wide enough.